ABOUT NIPPEN PIPE FITTINGS, PIPE AND FLANGES IN MUMBAI INDIA!!

- home

- About Us

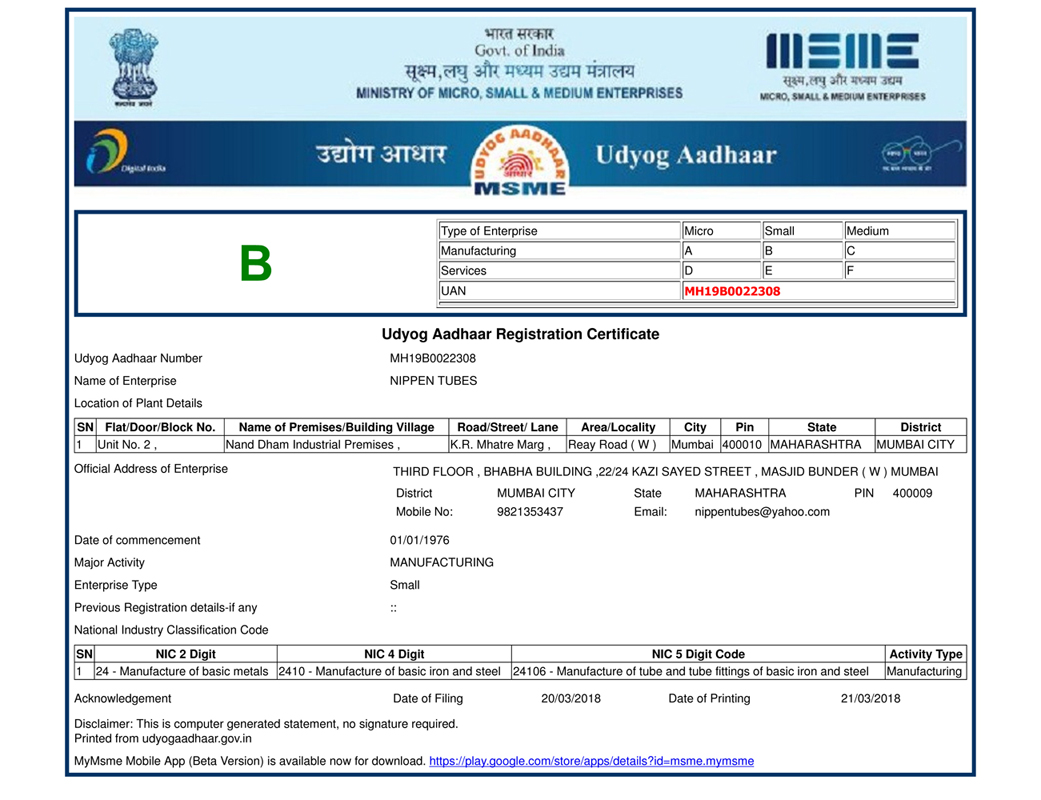

We - Nippen Tubes are manufacturing and supplying a wide range of ferrous and non ferrous metal products. Catering to various industrial projects in India and abroad, we have earned the reputation as a dependable Manufacturer / Supplier among our vast international client base. Nippen Tubes is leading Manufacturer and Exporter of Pipe Fittings, Pipe, Alloy Steel Flanges and Pipe Fittings in Mumbai India. We are growing manufacturing company in the field of carbon and alloy steel flanges, carbon steel and alloy steel pipe fittings and low temperature carbon steel and alloy stee; fittings and flanges. Our rich technical experience and organized production procedures has helped us become one of the most trusted supplier of Quality Pipe, Pipe Fittings, tubes and Flanges in India.

This position is earned due to our ongoing mission to offer consistency in quality for both our products and services. We offer a complete line of standard as well as customized metal products to our clients. Our comprehensive range of products includes Carbon Steel / Stainless Steel / Alloy Steel and Low Temperature Carbon Steel (LTCS), nickel alloys, etc. in shape of pipe, plates and pipe fittings.

Quality products and complete customer satisfaction is our forte. For ensuring these factors in our business process, we come with requisite facilities in terms of infrastructure and human resources. Head-quartered in Mumbai, it enables us to offer precision products in stipulated time-frame.

Application Area

Our wide range of ferrous and non ferrous metal products are used in various industrial operations. Offered in various specifications of industry standards & custom designed, these products can fulfil different requirements of the users. Our commodities meet various requirements of following industries:

• Engineering and Construction

• Automotive Industry

• Drilling and Well Building

• Chemical industry

• Power Plants

• Architecture

• Food Industry

• Aircraft and Aerospace Industry

• Oil and Gas Industry

• Paper and Pulp Industry

• Pharmaceutical Industry & biochemistry

• Pneumatic Conveyor Systems

• Pumps

• Ship Building Industry

• Water Treatment Plants

• Environmental Technology

Quality Control

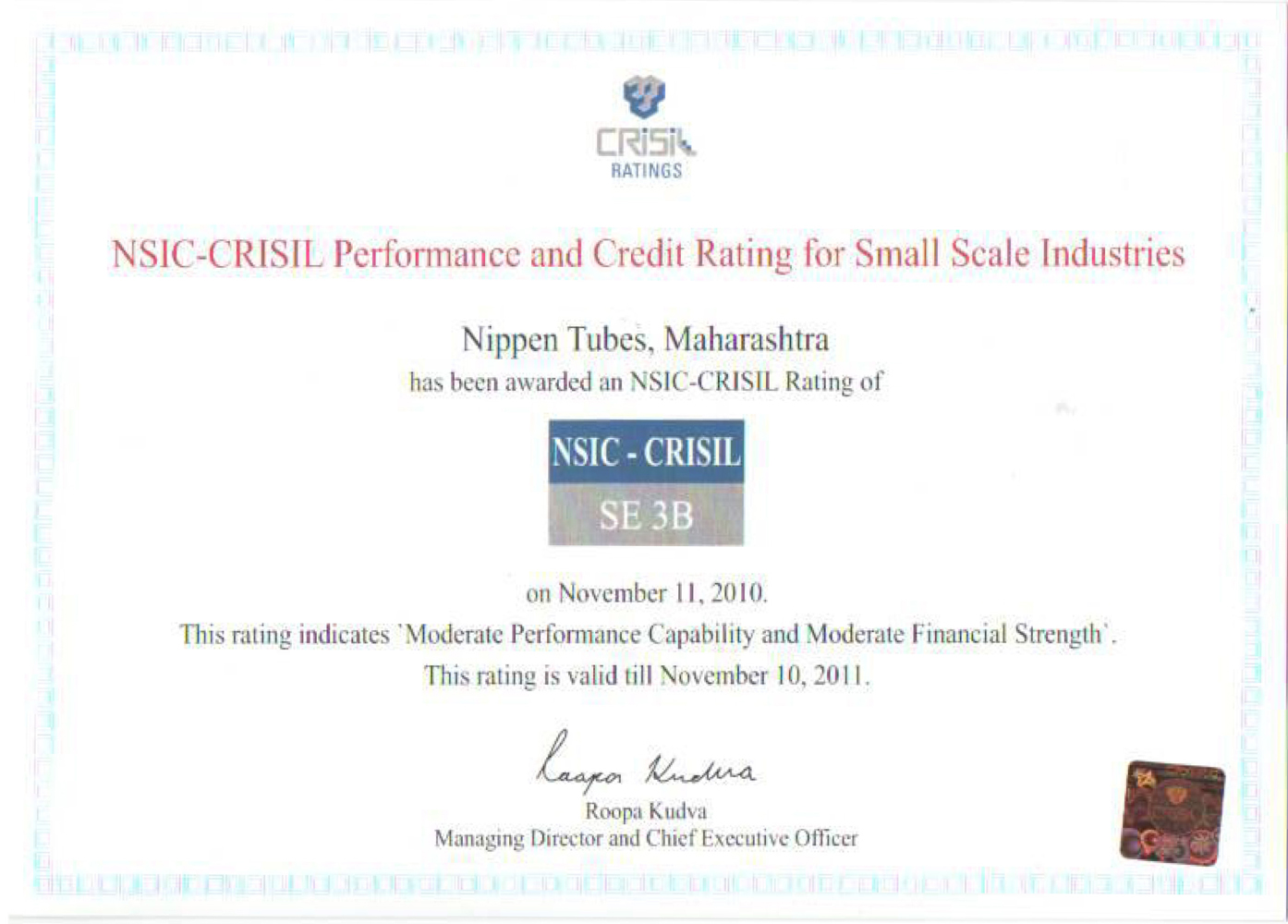

We are committed to furnish Excellent quality products at economical price with schedule consistency. It is our endeavor to follow the principles of total quality management. For our pursuance of Total Quality Management system, we have received ISO 9001 : 2008 certification. The company has developed quality objectives and work plans for quality management. We follow stringent quality control norms by reviewing and monitoring each production processes. This allows us to upgrade our quality processes to superior levels. Each product of our range is tested as per the internationally accepted standards using various test procedures. In addition, we also facilitate specific testing as per the client's requirement. For quality control, we have a team of quality checking staff.

Quality Assurance Plan

We employ the following testing procedure for ensuring effective quality in our product range :Raw Material Testing The raw materials, which are used to manufacture our range of fittings and other ferrous and non ferrous metal products, are tested to ensure requisite chemical and mechanical properties. For this, we use approved measuring instruments.Dimensional Inspection Each flange and fitting is checked for dimensional accuracy using calibrated measuring instruments offered by government approved calibration agencies. Hydro Test Up To 15000 Psi Various types of fittings, flanges and valves are tested at a proposed static pressure for a specified time period to ensure no leakage.Vibration Test We facilitate vibration test for fittings and valves, in which these products are tested for severe vibration under impulse pressure to ensure no leakage.

Special Testing

We offer special tests desired by our clients. These entire tests are certified by our quality control department. Some of these tests include :

Pneumatic Gas Test :The compressor & threaded fittings and valves are subjected to pneumatic tests at 150 psi air pressure and 2000 psi nitrogen pressure. This test is carried out after hydro testing.

Helium Gas Test (Hg-test) :We provide this test on special demand of our clients.

Pressure Cycle Test :Our range of fittings and valves is subjected to pressure cycle test, which is carried out from 0 psi to 5000 psi. Using digital counters, we conduct the test at the rate of 25 to 45 cycles per minute.

Temperature Test :We provide temperature test for fittings and valves on special request from clients. In this test the fitting & valves are heated up to 350 °C for one complete cycle of 4 hours.

Third Party Inspection

We offer third party inspection for our products. It could be of client's choice or we arrange the internationally renowned agencies such as Lloyds Register, Bureau Veritas, SGS, etc. The third party inspection agencies services under our scope include:

• BVIS

• TUV

• DNV

• SGS

• ABS

• GLC

• Bax Council

• CEIL

Infrastructure

Our well-furnished infrastructure is located in Mumbai. The excellent production unit enables us to cater to our clients with utmost precision. It enables us to offer standard and customized products. Our facilities includes:

• Machining Shop

• Quality Control Unit

• Warehouse

• Logistic Unit

Each production unit is managed with experienced professionals. Again, we use cutting-edge machines and tools for producing our range. The machinery at our manufacturing unit includes:

• Lathe Machine

• CNC machine

• Grinder

• Sheet Cutting Equipment

• Vernier Calliper

• 'D' Meter

• Measure Tape

• Testing Systems

• Allied Tools

Sourcing Capabilities

Our unprecedented success in the industry as a supplier of superior grade steel, non-ferrous and alloy products is columned on our quality orientation and customer oriented services. In order to fulfill the entire requirements of our clients with great precision, we import various products from the leading manufactures worldwide. We are importing and stocking various types of of stainless steel, carbon steel, alloy steel, non-ferrous metals and nickel alloys from the renowned manufacturing plants of Japan, Germany, Brazil and USA. Each production unit is managed with experienced professionals. Again, we use cutting-edge machines and tools for producing our range.

Why Us?

• ISO 9001:2008 certified company

• Provision for third party inspection

• Tie ups with international renowned third party inspection agencies

• World class production unit

• Team of proficient engineers, technicians and quality inspectors

• Imported quality commodities

• Precision engineered products at economical prices

WE ARE AN ISO CERTIFIED COMPANY !!!